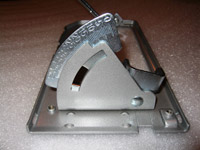

Constructed from C1008-1010 cold rolled steel (CRS) and Grade 80 high strength low alloy (HSLA) steel, this metal base assembly was designed to be used as part of a cordless trim saw. We used CRS that was .085″ thick and HSLA that was .120″ thick. Using our metal stamping and assembly capabilities, we produced four different metal stamped parts and assembled them by welding and riveting the parts into one assembly. We also applied secondary processes such as tapping, projection welding, zinc plating and powder coating in a silver finish. The final assemblies are packaged in egg crate type packaging for protection and delivery to the customer’s facility.

For this project we maintained manufacturing tolerances of ±.004″ and meet the JIT delivery for the 250,000 units required on an annual basis. For more information on our metal stamping services, please contact us or see the table below.